- CNC Machining

- Waterjet Cutting

- Welding

- Sheet Metal Fabrication

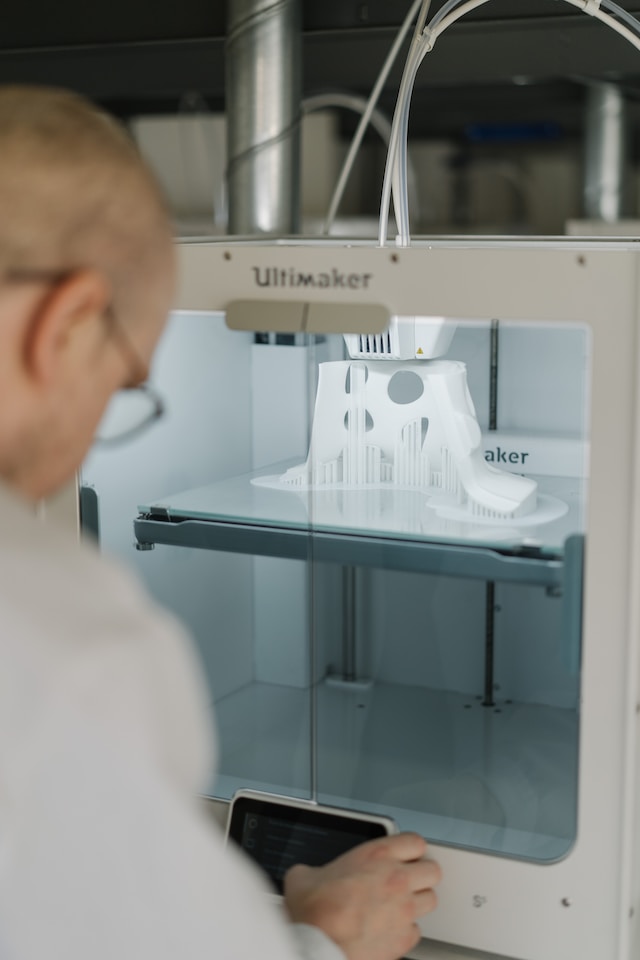

- 3D Printing

| CNC Machining | Waterjet Cutting | Welding | Sheet Metal Fabrication | 3D Printing | ||

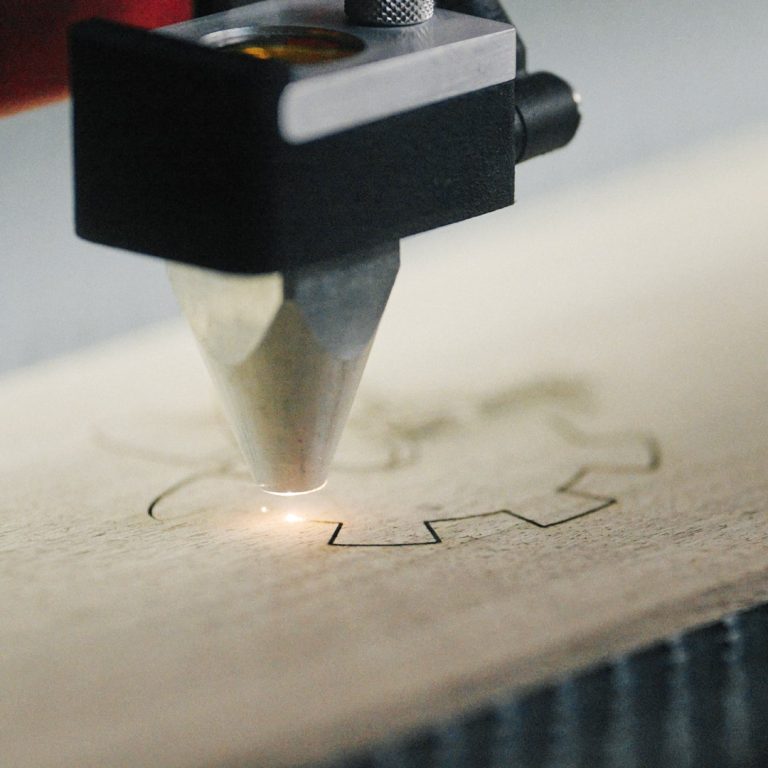

Laser | CNC Machining | Waterjet Cutting | Welding | Sheet Metal Fabrication | 3D Printing | |

| High precision and accuracy | ||||||

| Ability to cut intricate designs and patterns | ||||||

| Smooth edges and minimal material waste | ||||||

| Wide range of materials can be cut | ||||||

| Ability to create complex geometries |